| HTTU-315/3 | HTTU-315/4 | HTTU-450/4 | HTTU-630/8 | |

|---|---|---|---|---|

| Pipe Range (mm) | 32-315 | 75-315 | 90-450 | 225-630 |

| No. of Track | 03 | 04 | 04 | 08 |

| Contact length (mm) | 1500 | 1500 | 1800 | 1800 |

| Tractive force in KN | 15 | 25 | 25 | 40 |

| Haul-off Drive Power (kW) | 3.75 | 5.6 | 5.6 | 11.25 |

| Connected Power (kW) | 3.75 | 5.6 | 5.6 | 11.25 |

| Line Speed (m/min) | 2-16 | 2-16 | 1-10 | 0.5-5 |

| Required Space (Approx) Height (mm) Width (mm) Length (mm) |

2500 1500 3000 |

2500 1800 3000 |

2500 2000 3500 |

3000 3000 4000 |

| Extrusion Centre Height(mm) | 1100+/-50 | 1100+/-50 | 1100+/-50 | 1100+/-50 |

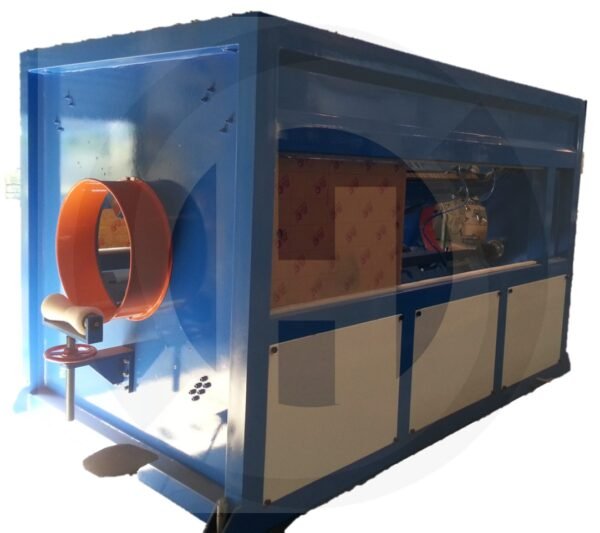

MULTI TRACK PIPE HAUL-OFF MACHINE

Details:-

Multi track pipe haul-off has been specially developed to pull at constant speed & synchronized with extrusion speed.

Standard Features:

- Multi belt Haul-off 3/4/6/8 belts for optimum pulling force and to prevent ovality even for large diameter and thin wall pipe

- Pneumatic clamping of pipe ensure ease in set up and efficient pulling of pipe

- AC Variable Frequency drive with AC geared motor

- Easily removable rubber pads / molded rubber chain

- Natural rubber pads

- Synchronization with any type of extruder

- A wide range of line speed is available and a required speed is selected very easily through AC frequency drive

- Mobile push-button remote

Optional Features:

- Neoprene rubber pads

- Special-shaped rubber pads

- Individual track drive with individual AC geared motor with AC drive/ AC servo motor with drive

- Thickening unit (by sowing down of the haul-off)

- Motorized positioning of lower tracks